Introduction

Universal x-carriage allows your choice of Bear or Prusa carriage with your choice of extruder. Bear/BNB, Prusa, and Bondtech upgrade extruders are supported....

Bunny and Bear Geared,

Bunny and Bear Short Ears

Bear

Prusa MK3 R3

Prusa MK3S R4

Bondtech I3 Upgrade

This BNB extruder x-carriage has belt paths for both Bear and Prusa x-axes. The upper one is for Bear x-axis, the lower one is for Prusa x-axis. Push belt ends into slot corresponding to your axis.

Because this is based on the BNB Easy Motor Service carriage for Bear extruder, you also gain simple motor bolt access for BNB and Bear extruders.

BNB Short Ears extruder should clear stock Prusa motor x-end when used with this carriage.

For Bear and BNB family extruders...

This carriage also moves extruder 1.5 mm closer to x-axis, but maintains same dimensions for most bolts inserted through x-carriage. Note that the 10 mm bolt just above bottom bearing that connects extruder body to x-carriage must be changed from 10 mm to 8 mm. That was the only Bear/BNB family bolt for which there was no clearance available to compensate for the thinner carriage.

For Prusa extruders...

Carriage still moves extruder 1.5 mm closer to x-axis, is thinner than Prusa x-carriages, and bolt mounting depths may differ from Prusa carriages. Consequently, you will need to shorten some bolts for proper fitment. Most obvious are the two MK3S bolts going through the hot end air duct. Please verify your bolt lengths before tightening. Also note that cable dress should be done "Bear" style rather than following Prusa conventions.

Combined with the BNB Short Ear Extruder's already pushed back motor, this carriage moves the motor to a fraction of a mm in front of the Z-axis T-nut

I have verified this carriage on both Bear and Prusa x-axes. It works as intended. Just be certain to use the correct insertion slot - Top for Bear, bottom for Prusa. Also, it is best to insert a short pit (two teeth long is sufficient) of belt into the empty slot BEFORE attaching belt ends.

Genuine Gates 2GT belts are thinner and much easier to insert than the Chinese GT2 belts I have in stock. I would build in more clearance for the belts, but there is very little space available without weakening the belt grips.

Testing on both axes reminded me why I switched to the Bear axis. It is SO MUCH easier to attach drive belt and get correct tension on the Bear axis. None the less, this universal x-carriage lets you run a BNB or Bear extruder on the Prusa x-axis.

As in the Skelestruder, you should stiffen the belt holding teeth of the carriage by stuffing the unused belt path with a two tooth long, piece of 2GT belt.

STL files for this item are at https://www.thingiverse.com/thing:361059...

Then geometry dash meltdown captivates players with its fast-paced gameplay, where timing and rhythm are essential for overcoming obstacles and progressing through the beautifully designed levels.

-

-

Bunny and Bear Universal X-carriage

-

Upper cover

-

Lower cover

-

Cable guide parts A & B

-

Process as usual for 3D printed parts. Some bolt holes now print with a sacrificial membrane to improve print geometry. Drill through membrane to open bolt holes. Most bores are 3 mm. Small leg of bottom rear cover has 2 mm bore.

-

Do not drill out hole for nylon support filament at end of cable guide

-

-

-

Optionally, remove intrinsic print support from hot end cable guide. Support snaps of easily with pliers. Smooth edge as needed.

Not sure if this part has changed since the instructions were written, but I did not appear to have to do this when assembling

Chris Champeau - Resolved on Release Reply

-

-

-

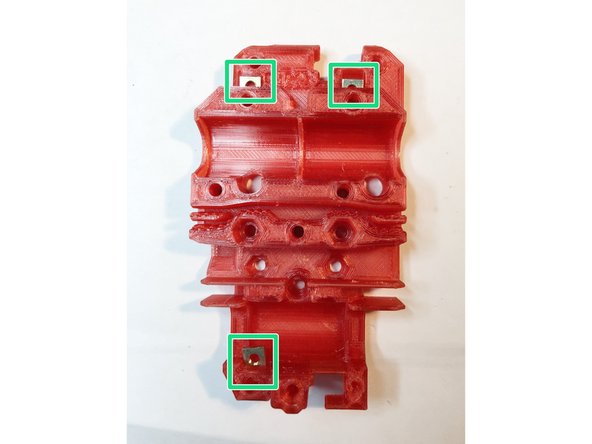

Embed four M3 nuts into front (flat mating surface) of x-carriage

-

These nuts must be fully seated into their pockets or 16 mm cover screws will not reach them. When fully seated they should be inset nearly 1 mm. Alternatively, 18 mm cover screws can be used, but design is for 18 mm.

-

If working in polycarbonate, elephant footing may require re-beveling entrance of each hex pocket with knife.

I believe there is a typo in this instruction:

Alternatively, 18 mm cover screws can be used, but design is for 16 mm.

Chris Champeau - Resolved on Release Reply

-

-

-

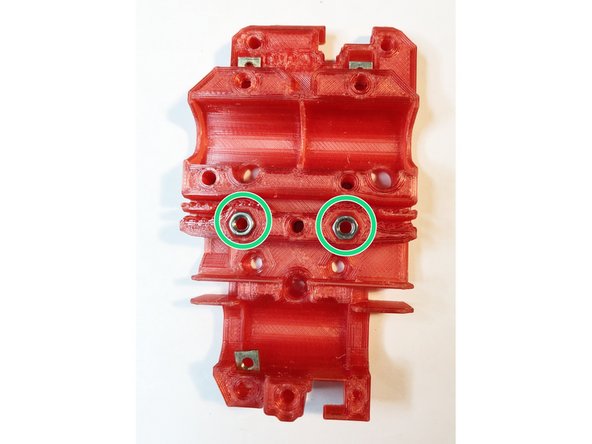

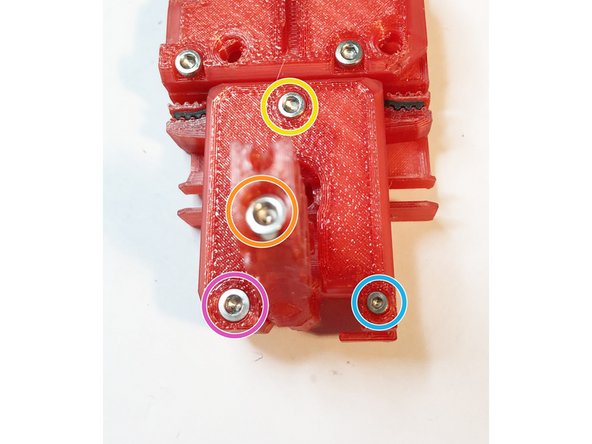

Insert three M3S square units into pockets. (Shown partially inserted)

-

Upper two M3S nuts have annoying tendency to fall back out after insertion. Bunnies avoid angry nut searches by locking them in place. Melt a bit of PETG filament into nut pocket entrance after nut insertion.

-

-

-

This step is ONLY if using R4 style bodies (Prusa R4, Butterworth, Bunny and Butterworth, Bondtech Prusa Upgrade), add two extra M3 nuts.

-

DO NOT INSERT THESE NUTS FOR BNBSX or BNB Short Ears extruders. BNBSX will use these holes "backwards" to pass a bolt directed forward.

-

M3 nuts for Prusa R4 style hot end screws.

-

-

-

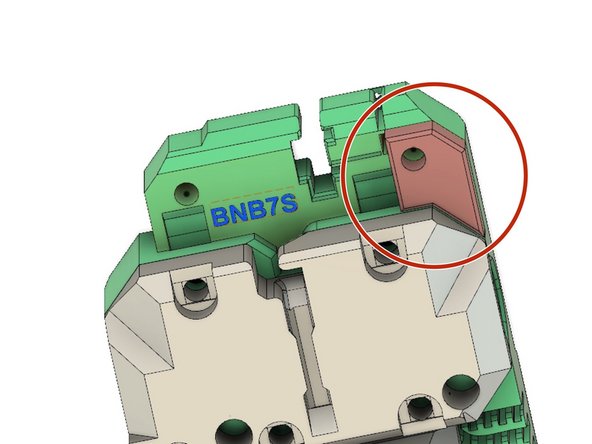

BNB Universal X-carriage works with both MK3 laser and MK3S IR filament sensor boards. However, MK3S is in different location and needs different access slot for cable.

-

Score and remove breakaway tab from x-carriage to make it MK3S compatible

-

Smooth edges as needed with blade or abrasive.

-

-

-

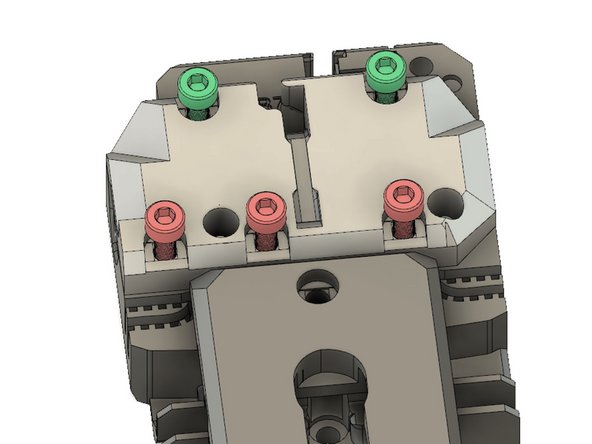

This carriage adapts to either Prusa or Bear style x-axes via Skelestruder-like dual belt clamp positions.

-

Use upper belt clamps for Bear x-axis. Bunnies MUCH prefer Bear x-axis for its superior tension adjustment system.

-

Use lower belt clamps for Prusa X-axis

-

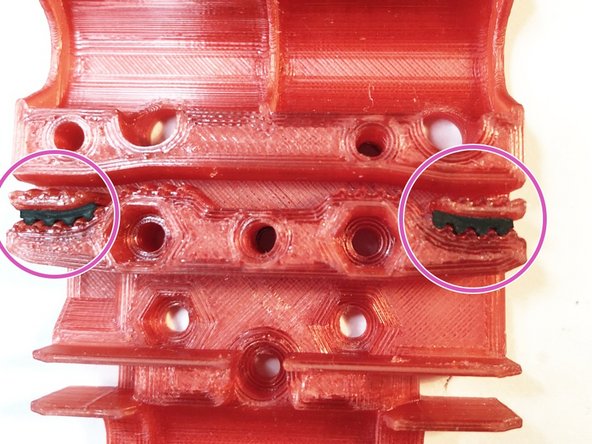

Before inserting x-belt, strengthen the clamp system with 4 tooth pieces of GT2 belt. Otherwise, you risk eventual fatigue failure.

-

Insert belt segments at entrance to each side's x-belt clamp path NOT being used.

-

-

-

Pre-fit all cover screws now to verify all cover screws properly engage their respective nuts. Don't wait until actual installation on x-rods.

-

Two M3 x 12 mm top cover screws. (10 mm is OK)

-

Flat portions of screw pockets are printed as overhangs. Depending on printer and filament, you may need to clear out stray or misshapen plastic with knife.

-

Three M3 x 18 mm top cover screws. If these do not engage nuts, recheck nuts are fully seated and pocket flat free of debris.

-

M3 x 16 mm bottom cover screw

-

M3 x 12 mm bottom cover large leg screw

-

M2 x 12 mm bottom cover small leg screw. This screws directly into plastic. There is no nut. Be gentle.

-

M3 x 40 mm cable guide screw

Per a previous step, I am pretty sure the three M3 x 18 mm top cover screws are actually supposed to be three M3 x 16mm screws, that worked for me and as mentioned earlier it is designed for M3 x 16mm screws

Chris Champeau - Resolved on Release Reply

-

-

-

ONLY for BNBSX Short Ears Extruder

-

Spacer allows use of standard length M3 x 30mm screw here instead of custom length screw.

-

-

-

Congratulations, your Bunny and Bear Universal X-carriage is ready for use.

-

Cancel: I did not complete this guide.

4 other people completed this guide.

15 Comments

It is not only the races in Kart Bros. that provide tremendous thrills, but they also build a culture of competitiveness, camaraderie, and the joy of triumph. In addition to providing participants with opportunities to create unforgettable moments with their fellow drivers, each course is meant to test their driving abilities, strategies, and reflexes.

Thanks for putting this together. I’ve been exploring free PHP hosting services for a small project, and your insights helped me understand what features actually matter. Really appreciate the clear breakdown!

Deepika verma - Open Reply

bloodmoney! has completely redefined what I expect from a clicker game. The balance of humor and horror is masterfully done, making each interaction with Harvey both entertaining and nerve-wracking. I appreciate the strategic depth that comes with the simple mechanics. It's a refreshing take on the genre that keeps me hooked!

With Sprunki Retake, the power of composition is at your fingertips, ready to unlock soundscapes by simply dragging and dropping vibrant icons onto a living canvas. Create subtle beats, soaring melodies, and experimental sounds without any formal training. Unleash your inner musical genius, one icon at a time.

SprunkiRetake - Open Reply

This guide on the BNB Universal X-Carriage is incredibly detailed and helpful! I appreciate how it breaks down each step clearly, making it easier to follow along. It reminds me of when I took the rice purity test, reflecting on how preparation can make a big difference in achieving good results. I'm excited to try this out and see how it enhances my printing experience!

Davis Jame - Open Reply

Players may explore imaginative and difficult golf courses in the entertaining golf game Golf Orbit. The game provides hours of amusement for both novice and expert golfers with its easy-to-learn yet difficult gameplay.

The competitive nature of head basketball keeps players coming back for more, as they strive to improve their skills and rankings.

With split-second differences deciding winners, the thrill of shaving off just 0.01 seconds from your best time is real in Speed Stars

Gabrielle Finley - Open Reply

There would be more room to accommodate the belts without compromising the strength of the belt grips, but unfortunately, that is not possible. Playing Melon Sandbox will test your culinary creativity and problem-solving abilities as you try to increase your harvest by combining different ingredients in novel ways.

Steven Snyder - Open Reply

Thanks for your information! Everyone in the community praised the tiny games. A suitable environment for your development

Thank you very much for the useful information that the blogs have shared. I have a gift for you Pizza Tower.

If you are looking for the best travel insurance company then you must visit https://traveldefend.com/ website for amazing offers and services.

Nice but that didn’t work as you have been taking some ideas from this source. By the way, I am a student and I was searching for some graphically designed t shirt and my friend told me about the MasterBundles source where I can try plenty of t shirt as of my interest. If you are searching for the same then go with this.

Albert kutta - Resolved on Release Reply